Quy trình lắp đặt thang máy

Quy trình lắp đặt thang máy Trước khi thang máy được lắp đặt, phía bên nhân viên kỹ thuật lắp đặt cầu thang của nhà cung cấp và chủ đầu tư cần được biết các công việc cũng như quy trình lắp đặt toàn bộ cầu thang máy. Tất cả các giai đoạn từ lúc thiết bị thang máy được tập kết đến lúc công trình được thi công lắp đặt thang máy xong, để những ai liên quan đến công trình có thể kiểm soát được tiến độ, chất lượng công trình và trên hết là an toàn lao động của những người tham gia.

Những thông tin của bài này sẽ giúp cho mọi người có thể hình dung bao quát các công việc khi lắp đặt thang máy. Bạn có thể tham khảo quy trình thang máy được lắp đặt sau đây.

I. Chuẩn bị các yếu tố an toàn khi thang máy được lắp đặt:

1. Cửa hố thang máy phải được che chắn kín và chắc chắn trong quá trình thi công.

2. Giếng thang phải được bố trí đủ ánh sáng trong quá trình thi công.

3. Các thao tác trong quá trình thi công phải được thực hiện đúng về tiêu chuẩn kỹ thuật như hàn điện, nâng kéo vật nặng (không được làm tắt dễ gây nguy hiểm cho người khác cũng như bản thân mình và thiết bị).

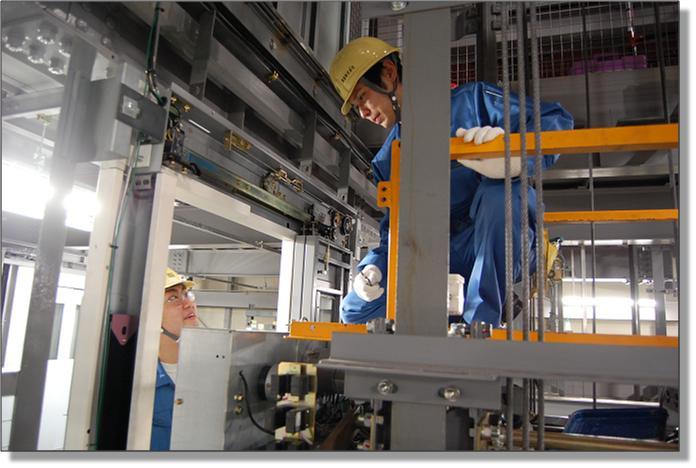

4. Tuyệt đối phải mang các thiết bị an toàn, mũ quần áo bảo hộ, dây an toàn trong quá trình làm việc.

5. Cáp an toàn phải được thả dọc hố thang và sử dụng trong suốt quá trình thi công.

6. Tuyệt đối tuân thủ nội quy an toàn tại công trình làm việc.

7. Trong quá trình thi công, các tổ trưởng phải kiểm tra, thực hiện tốt các yêu cầu về an toàn lao động.

II. Kích thước hố thang.

- Kiểm tra các chướng ngại vật trong hố thang, phòng máy.

- Các vấn đề khác như: lỗ chừa kéo máy, lỗ cho các thiết bị tín hiệu tại các cửa tầng, kích thước cửa tầng, móc treo pa-lăng, kích thước đấy giếng, chống thấm, phòng máy, điện nguồn.

1. Chuẩn bị: các dụng cụ, thiết bị vào đúng vị trí thi công (palan, máy hàn, máy khoan và các dụng cụ phụ khác).

- Chuẩn bị các nguồn điện thi công.

- Vị trí điện nguồn.

- Công suất điện nguồn.

- Nối điện máy hàn và dụng cụ khác.

- Thắp sáng hố thang.

- Thả dây cáp an toàn dọc hố thang.

- Đóng dàn thao tác.

- Kéo các thiết bị lên phòng máy.

2. Đưa động cơ, tủ điều khiển lên phòng máy: Dùng pa-lăng đưa động cơ, tủ điều khiển, cáp tải lên phòng máy

3. Xác định vị trí và lắp giàn chuẩn

- Lắp giàn chuẩn trên cùng: Giàn chuẩn trên cùng sẽ được đặt ở tầng cao nhất (bên dưới sàn phòng máy).

- Lắp giàn chuẩn bên dưới: Giàn chuẩn bên dưới sẽ được lắp đặt ở pit hố thang.

4. Đặt máy kéo, tủ điều khiển vào vị trí: Định vị máy kéo, tủ điều khiển căn cứ theo bản vẽ thi công.

5. Lắp hai ray dẫn hướng đầu tiên

- Dùng giàn giáo để định vị bracket.

- Lắp đặt hai ray dấn hướng đầu tiên cho Car và CWT

6. Lắp khung cabin và khung đối trọng

- Lắp khung đối trọng.

- Lắp khung cabin: Lắp khung sàn cabin (có bộ phận phanh an toàn); Thanh khung đứng; Thang giằng; Khung trên; Làm bảo vệ sàn cabin.

7. Lắp hệ thống phanh an toàn bộ khống chế vận tốc: Lắp hệ thống phanh hãm an toàn dưới khung cabin, bộ khống chế vượt tốc và kiểm tra thử khả năng hoạt động của hệ thống.

8. Lắp cáp tải: Khung đối trọng nằm ở tầng dưới cùng, khung car nằm ở tầng trên cùng và sẽ được đặt ở vị trí cố định bởi palan cho đến khi hoàn tất việc lắp cáp tải.

9. Lắp ray dẫn hướng

- Tập kết ray dẫn hướng vao khu vực giếng thang.

- Dùng khung sàn cabin đã lắp hệ thống phan an toàn để lắp ray dẫn hướng còn lại.

- Ray dẫn hướng sẽ được lắp từng thang một bằng cách sử dụng pa-lăng điện để kéo chúng vào đúng vị trí.

10. Lắp đặt cửa tầng

- Tất cả các thiết bị cửa tầng sẽ được chuyển đến trước mỗi cửa tầng.

- Sau khi lắp cáp tải, chúng ta sử dụng sàn car để lắp cửa tầng.

- Lắp từng cửa và theo trình tự từ trên cùng xuống đến cửa tầng thấp nhất

11. Lắp đặt hệ thống dây điện.

- Lắp dây động lực cho cụm máy kéo

- Lắp dây điều khiển ỏ trên phòng máy

- Dùng khung cabin lắp dây điều khiển ở trong giếng thang và theo trình tự t từ trên xuống.

- Lắp các thiết bị tín hiệu tại cửa tầng.

- Lắp cáp động trong giếng thang.

12. Lắp vách cabin, cửa cabin và bảng điều khiển trong cabin.

- Sàn cabin đặt tại tầng thấp nhất.

- Vệ sinh sạch sẽ.

- Lắp vách car, nóc car.

- Lắp cửa cabin và hệ thống động cơ cửa.

- Lắp bảng điều khiển trong cabin.

- Đấu nối hệ thống dây dẫn.

13. Kiểm tra, hiệu chỉnh.

-Vệ sinh từ trên xuống.

- Kiểm tra và hiệu chỉnh các thông số kỹ thuật.

14. Chạy thử thang.

- Sử dụng các thiết bị đo kiểm tra lần cuối trước khi cho thang chạy thử (trường hợp nếu có phát hiện gì dù là nhỏ nhất cũng không được cho thang chạy).

- Nghiêm cấm việc đóng điện chạy thang tùy tiện.

15. Kiểm định thang máy

Trước khi tiến hành bàn giao công trình cho chủ đầu tư để đưa vào sử dụng, thang sẽ được kiểm định và cấp giấy phép sử dụng thang máy. Công việc sẽ được tiến hành bởi Thang tra Nhà nước về An toàn lao động của Bộ LĐTBXH nhằm đảm bảo thang máy được lắp ráp theo đúng tiêu chuẩn về an toàn trong thang máy của Nhà nước Việt Nam.

16. Bàn giao thang máy: Làm vệ sinh, chạy thử và căn chỉnh lại nếu cần thiết. Chuẩn bị hồ sơ hoàn công để chính thức ban giao cho khách hàng đưa thang máy vào sử dụng.

>> Như vậy, bạn đã nắm được bao quát quy trình lắp đặt thang máy khi bạn có nhu cầu lắp đặt thang máy tải khách hay thang máy gia đình cho các công trình của bạn. Bạn sẽ biết được tiến độ thi công như thế nào để tiết kiệm thời gian tốt nhất có thể.